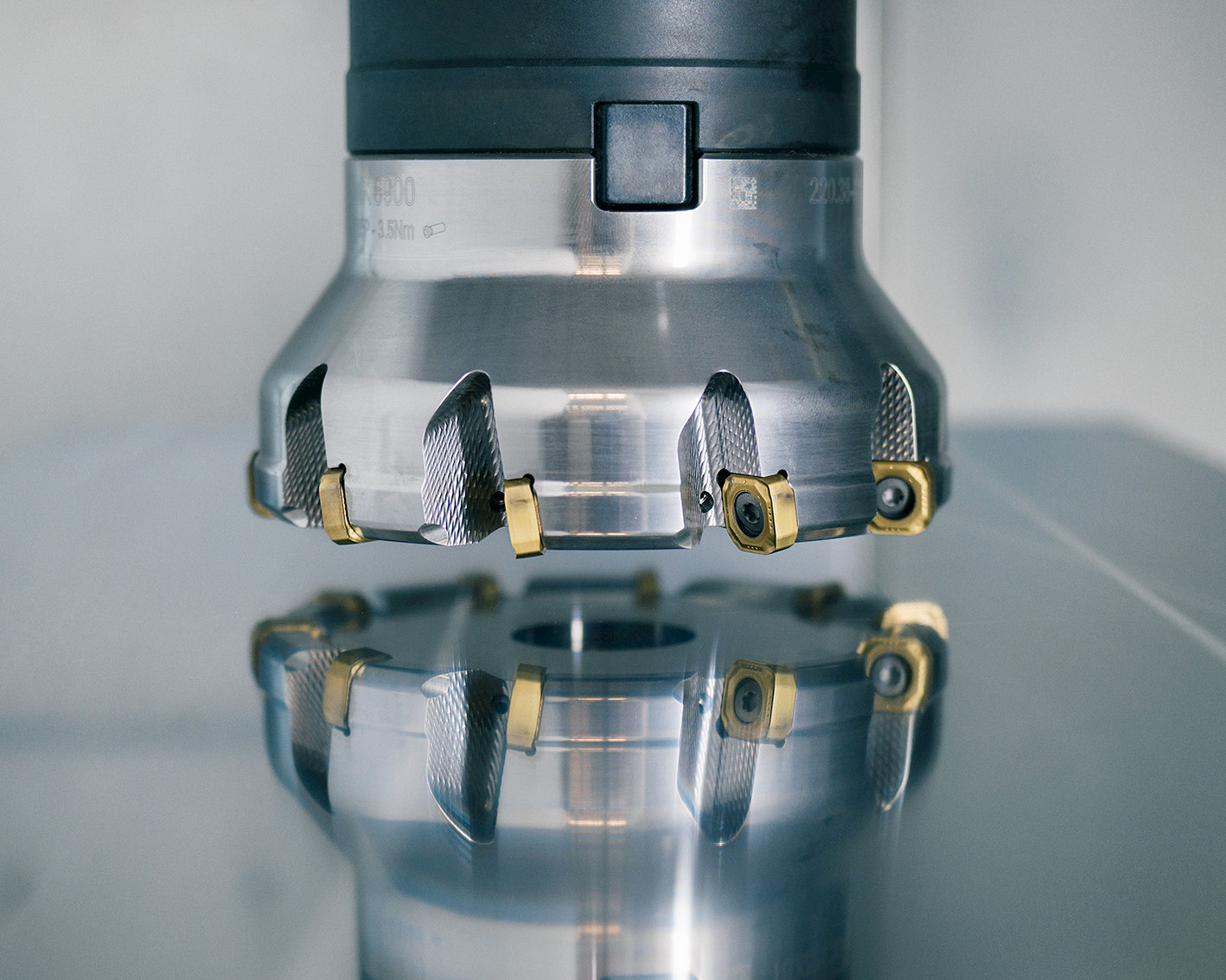

The .38 Finishing Face Mill: Consistent Surface Finishes with Minimal Effort

Seco is proud to announce the launch of the .38 Finishing Face Mill system, a selection of cutters engineered for high-precision surface finishing.Fagersta, September 16th - Seco is proud to announce the launch of the .38 Finishing Face Mill system, a selection of cutters engineered for high-precision surface finishing. With ready-to-use simplicity, hybrid flexibility, and ultimate adjustability, this system is designed to meet the full spectrum of finishing needs—efficiently and flawlessly.

The .38 Finishing Face Mill / SNFX1204 system offers three cutter variants—fixed pocket, hybrid, and adjustable—each tailored to different levels of control and performance.

The .38 Finishing Face Mill / SNFX1204 system offers three cutter variants—fixed pocket, hybrid, and adjustable—each tailored to different levels of control and performance.

Whether your priority is achieving consistent surface finishes or minimizing setup effort, this system offers a practical and flexible solution.

Offering two insert types to meet different demands— one with an 88° lead angle for near-wall machining and another with a 27° lead angle for high-feed, open-surface work—you can cover a wide range of finishing challenges while keeping operations simple and cost-effective.

- The Fixed Pocket Cutter (R220.38-….-SN-..SA) is ideal for users seeking effortless handling and setup-free operations. Its tilted screw design ensures perfect insert self centering and excellent run-out accuracy (4–15 µm), making it a cost-efficient solution that reduces operator error and training needs.

Inline Content - Gridded Links

Tags: '.38-sa fixed pocket'

Max links: 1

- The Hybrid Cutter (R220.38-….-SN-..CSA) combines fixed and adjustable cassette pockets, allowing it to function as a fixed pocket tool by default. The cassette inserts act like dedicated wiper inserts for enhanced surface finish and, while adjustment is possible, it’s not required—offering flexibility without added complexity.

Inline Content - Gridded Links

Tags: '.38-csa cassette pocket'

Max links: 1

- The Adjustable Cutter (R220.38-….-SN-..HSA) offers ultimate control, with fine tuning capabilities that achieve run-out as low as 0–2 µm—perfect for demanding applications where surface perfection is non-negotiable.

Inline Content - Gridded Links

Tags: '.38-hsa adjustable pocket'

Max links: 1

- The Plug and Play Cutter (R220.38-....-SN12-..WA). With the fixed pocket variant, setting up is easy and fast. No extra steps are needed. After choosing the insert, you can start over with an excellent run-out. The wedge clamp cutter is engineered with an super-close pitch design, delivering high performance and extended tool life. Optimized for short-chipping materials such as cast iron, it ensures maximum efficiency and reliability in demanding machining applications

Inline Content - Gridded Links

Tags: '.38 - wa fixed pocket - wedge clamping'

Max links: 1

“With the .38 Finishing Face Mill system, we’ve focused on making high-performance finishing both easy and dependable,” says Tobias Jakobi, Product Manager Face Milling at Seco.

“Ease of handling is essential in finishing operations, and this solution gives users the flexibility to meet varying demands—often with just one system where two might have been needed before.”

The .38 Finishing Face Mill system will be available globally starting in September 2025.