Getting Technical - The boring advantage : precision, repeatability, and control where it counts most.

Precision boring is a cornerstone process when finishing critical precision parts, but when it comes to large components, often produced in one-part batches, mastering the use of huge boring bridges is critical.

These big tools bring unparalleled possibilities, but also unique challenges.

This live event is about the essentials of boring technology, with a special focus on a practical success realization of an with a big boring bridge.

From setup and tool selection to vibration management and troubleshooting, attendees will gain actionable insights to optimize their boring processes, reduce risk, and enhance quality, even under the pressure of one-off production.

Register on LinkedIn

Related content

Why geometry is the undisputed champion of efficient machining?

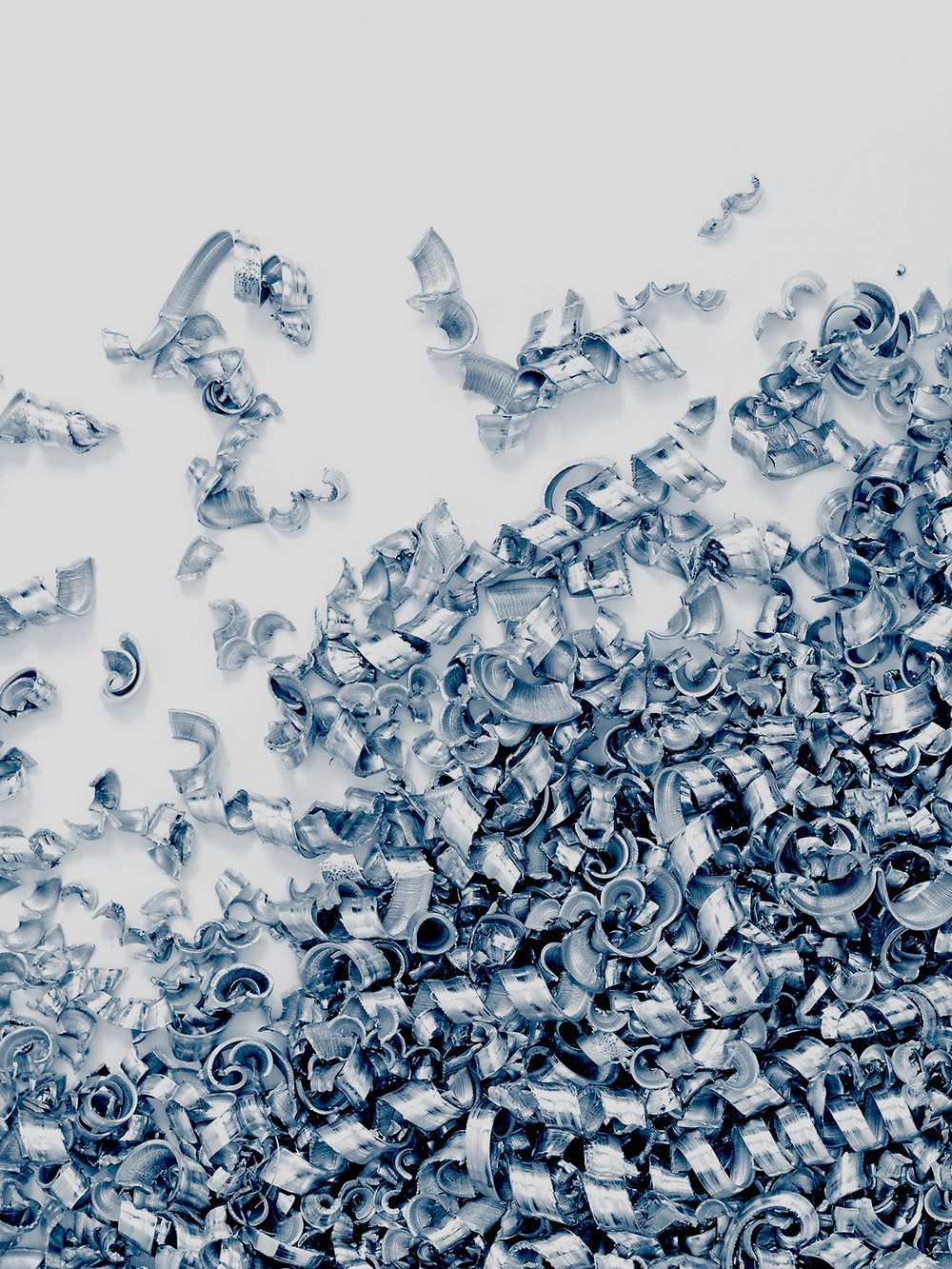

The silent saboteurs. How bad chip control destroys profits and tools

Optimised machining data for small batch production

Profitable small batches, can efficiency and sustainability coexist?

Milling Cutter positioning. What it is? And why is it so important?

Machining strategies for small batches of high-quality parts

Tool life maximisation through smart tool life cycle management

Advances in superalloy machinability

Reducing the climate impact of manufacturing utilizing life cycle analysis

Getting Technical

Part 2 - Structural analysis of tool deterioration: strategies for optimal machining performance

Part 1 - Structural analysis of tool deterioration: strategies for optimal machining performance

Part 1 - What you don't know about tool holders could hurt your manufacturing!

Machining mastery explored: Model-based machining advancements

Part 2 - What you don't know about tool holders could hurt your manufacturing!

Part 2 - Take full profit of advanced cutting materials

Machining Economics part 2

Technical Machining Strategy Part 1

Technical Machining Strategy Part 2

Part 1 - Take full profit of advanced cutting materials